Technological progress is growing exponentially today, and this century has brought innovations that are transforming the world of manufacturing. The past two centuries have been marked by numerous technological advances that have made manufacturing the backbone of the modern economy.

The Role of MESA Electronic GmbH in Technological Development

MESA Electronic GmbH is at the forefront of technological progress, adhering to Industry 4.0 standards and IoT solutions. The term 'Industry 4.0' was first introduced in 2011 by the German government to enhance the production and growth of the German manufacturing industry. This initiative signifies the rise of smart factories, where interconnected machines automate processes, increasing efficiency and reducing costs.

Industry 4.0 also plays a crucial role in the heat treatment sector by enabling more precise control of furnace atmospheres, ensuring consistent quality, and reducing energy consumption. One of the key advancements in this field is predictive maintenance - a system that uses data from sensors to predict equipment failures before they occur. This minimizes downtime, extends equipment lifespan, and lowers operational costs. By integrating predictive maintenance tools, manufacturers can proactively address issues, reducing unplanned interruptions in production.

What Does Industry 4.0 Mean for Your Production?

In modern manufacturing plants, everything is highly interconnected. Precision and faster production lead to higher profits for both manufacturers and end-users. With over 50 years of experience, MESA Electronic GmbH offers customized measurement and control systems in gas analysis for heat treatment, including carburizing, nitriding, dew point, and oxygen control.

Real-World Example: Customized Systems for Heat Treatment

Scenario: A heat treatment department aims to modernize the gas measurement system across multiple furnaces (e.g., 3-5 or more). Key parameters include CO, CO2, CH4, H2, and dew point, which need to be continuously available online and integrated with control and maintenance systems.

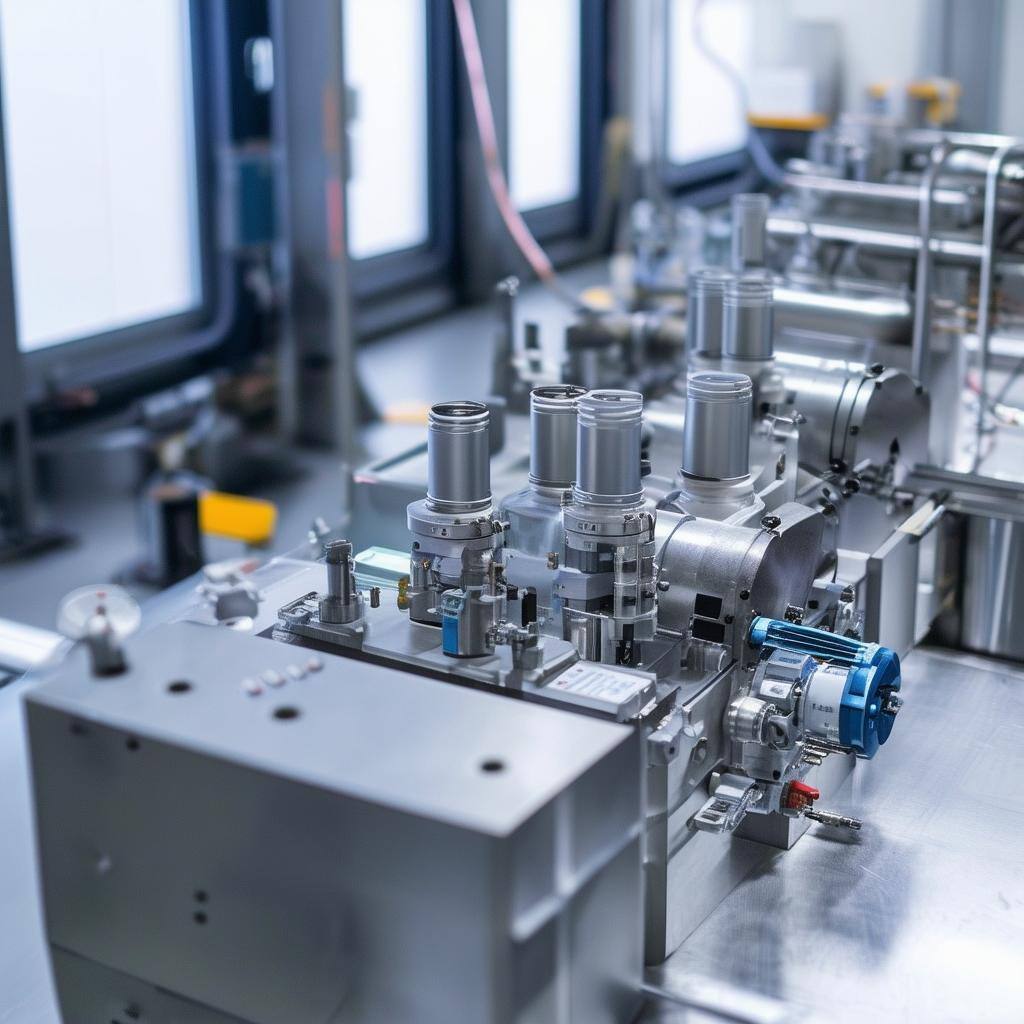

Standard Solution: Each furnace can be equipped with a dedicated gas cabinet or a multifunctional device (MGas 5.x). However, this solution can be costly for larger facilities.

Our Solution: Rather than installing individual devices for each furnace, MESA Electronic GmbH offers a multiplexing system that measures the atmosphere in multiple furnaces simultaneously. This system is a cost-effective solution as customers only need to purchase one device, reducing maintenance costs and saving time.

Key Benefits of Customized Solutions:

Cost Reduction

Having one device for multiple furnaces can save you money on both the initial cost and the maintenance costs.

Increased Efficiency

Faster analysis and automatic data transfer in real-time.

Flexibility

Systems adapt to the specific needs of each production line.

Tangible Results

Greater precision and reduced losses during the heat treatment process.

Examples of Personalized Products and Their Advantages:

- Automotive Manufacturing: Custom sensor networks that monitor production lines, improving quality control and reducing waste.

- Aerospace Industry: Tailored gas analysis systems ensuring optimal conditions for metal part fabrication.

- Biomass Boilers & Energy Plants: Customized oxygen monitoring solutions that enhance process consistency.

Generic measurement devices are often built to fit a wide range of use cases, but they may lack the precision or adaptability required for specific production environments. Custom products, on the other hand, are designed to integrate seamlessly with existing processes, ensuring higher accuracy and performance. For example, in heat treatment, a tailored gas analysis system can account for specific furnace configurations, leading to better atmosphere control and product quality. This results in reduced energy consumption and fewer production defects.

Who Benefits Most from Personalized Products?

Small to Medium Enterprises (SMEs)

Cost-effective solutions that scale with growth

Large Manufacturers

Greater integration across large-scale facilities

Specialized Industries

Unique solutions tailored to niche production processes

We are at any time ready to answer your questions or assist you with technical support - CONTACT US